Peking University, April 14, 2022: A joint team led by Prof. Wu Kai and Assoc. Prof. Zhou Xiong at the College of Chemistry and Molecular Engineering, Peking University, and Li Yongwang at Synfuels China Technology Co., Ltd. have employed, for the first time, innovative technology in surface chemistry to visualize ethylene polymerization on the surface of ordered iron carbide at the molecular level. The key mechanistic steps in ethylene polymerization have been clarified, including chain initiation via molecular isomerization and chain propagation via molecular insertion. The research results were published in Science on March 10, 2022, with the title "Visualization of On-surface Ehylene Polymerization through Ethylene Insertion" (DOI: 10.1126/science.abi4407). The same journal issue also published a perspective piece by Prof. Joost Wintterlin of Ludwig Maximilians-Universität München. (DOI: 10.1126/science.abo2194).

Polyethylene is the key raw material of plastic products, with a yearly output of 100 Mt worldwide, and is widely used in our daily lives. Ethylene polymerization, a common way to produce polyethylene, is a typical chain polymerization reaction that includes the fundamental steps of chain initiation, propagation, and termination. It is divided into free radical polymerization and coordination polymerization. In coordination polymerization, chain propagation follows the Cossee-Arlman mechanism, that is, ethylene is inserted into the metal-carbon bond that connects the growing polyethylene chain, while the metal center in the catalyst facilitates monomer polymerization. But the polymer science community has long been eluded by the fundamental issue that how to achieve chain initiation over Phillips catalysts for ethylene polymerization without alkyl aluminum as the initiator.

With in situ visualization technology, ethylene polymerization can be studied in real time, providing a great impetus for uncovering the ethylene polymerization mechanism. However, the chain anchored on the catalyst surface, through the active reaction center, which subsequently grows rapidly unidirectionally, makes it difficult to visualize well-ordered surfaces at the sub-molecular level.

Thanks to the long-term advanced technological accumulation in surface science by Wu Kai’s group and the rich understanding of the Fischer-Tropsch synthesis by Li Yongwang's group, the researchers became keenly aware that the Fischer-Tropsch synthesis could be envisioned as a polymerization of CH2, and that its catalyst iron carbide could serve as a model catalyst for the exploration of on-surface ethylene polymerization. Thus, it is possible to visualize on-surface ethylene polymerization on a molecular scale.

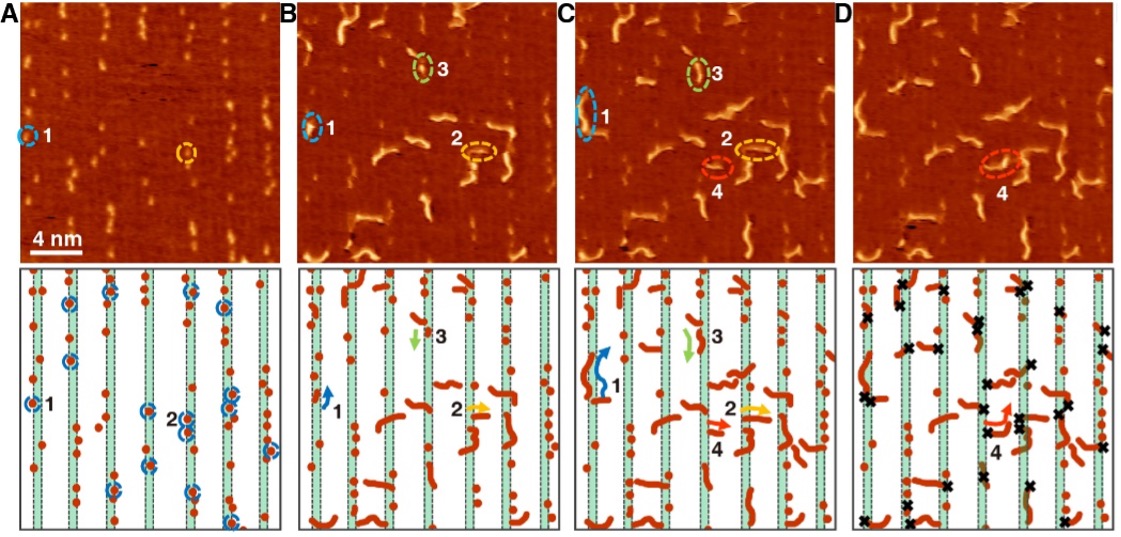

The researchers selected an atomically flat iron carbide thin film fabricated through carbon aggregation from a bulk Fe(110) single crystal. The iron carbide surface consisted of parallel domain strips separated by narrow boundary strips. Using state-of-the-art high-resolution scanning tunneling microscopy (STM), angle-resolved X-ray photoelectron spectroscopy, and density functional theory (DFT) calculations, the domain structure was determined to best resemble the θ-Fe3C(102) surface. Subsequently, in situ STM images of the carburized Fe(110) surface under 1 × 10−8 mbar of ethylene (C2H4) at room temperature were continuously recorded at a rate of one frame per 35 s (Fig. 1). Initially, the protrusions appeared exclusively at the boundary and then grew into short chains, implying that these boundary-anchored species acted as initiators for polymerization. The number and length of the chains increased as the reaction proceeded. One end of the polyethylene chain was tethered to the boundary, and the other grew peristaltically, showing a typical unidirectional growth mode. Furthermore, it was noticed that once polymerization was initialized, its subsequent chain growth became very rapid, which emphasized the characteristics of the chain-reaction polymerization mechanism. Both research groups systematically conducted low-temperature STM characterizations and DFT calculations to unambiguously identify surface species and reaction sites.

Fig. 1 Scanning tunneling microscopy (STM) snapshots of the carburized iron surface exposed to ethylene (C2H4) at room temperature. Video frames selected from the STM movie at 35, 245, 385, and 420 s.

All of the experimental and computational results fit the scenario in which a C2H4 molecule is inserted into the initial CHCH3 intermediate at the triangular site to form a chain (Fig. 2). This also explains how polyethylene is formed without the use of an activator via ethylene self-initiation over the Phillips catalyst. These results confirm the molecular insertion mechanism for ethylene polymerization, reveal self-initiation through ethylene isomerization in the absence of an initiator, and clarify the scientific debate regarding the chain initiation process over Philips catalysts. Additionally, this study indicates that the interaction between polyethylene and the catalyst can be tailored and exploited to terminate the polyethylene chain at a specific length, thereby, greatly improving the product chain length selectivity and providing a method for controlling the product chain length distribution.

Fig. 2 Illustration of the ethylene polymerization mechanism on the surface of ordered iron carbide.

Guo Weijun, a Ph.D. student at Peking University, and Yin Junqing, a Ph.D. student at the Institute of Coal Chemistry, are co-first authors of this paper. Wu Kai and Zhou Xiong are the co-corresponding authors. Part of this research was conducted by Guo Weijun at Synfuels China Technology Co., Ltd. This research was jointly supported by the National Natural Science Foundation, Ministry of Science and Technology, and Beijing National Laboratory for Molecular Sciences in China.

Edited by: Ye Yimeng

Source: PKU College of Chemistry and Molecular Engineering